Are you a brewer who is interested in finding out how much it costs to get started with a commercial brewing business? If so, then you’ve come to the right place! In this blog post, we’ll take an in-depth look at some of the equipment used in commercial beer breweries and what kind of budget one needs to anticipate when planning a brewery.

We will discuss both necessary and optional pieces of gear as well as their associated expenses. By the end, you should have a better idea about how expensive starting up a successful brewery can be.

So pull up your chair and grab your favourite beer–let’s dive into understanding commercial brewing operations!

Breweries can be found throughout the world, and they range in size and style. A large, industrial, worldwide brewery will likely employ many people working in various departments. This brewery will be organised into sections, each focusing on a specific set of operations and whose employees will see that those procedures are carried out only for their department's stage.

Craving some craft beer and spirits? Visit us today at Tar Barrel Mornington Brewery & Distillery for an unforgettable experience with craft beers, spirits and more!

The Initial Investment Required To Begin Brewing Commercially

It can easily reach from $100,000 to $1,000,000 depending on the size of your brewery, obtaining a licence, and purchasing high-quality commercial brewing equipment. To reiterate, this is a rough estimate.

The microbrewery is the superior option for someone just getting started in this field. Although it's a little cramped, you'll still have room to keep an eye on things.

You can get away with making fewer than 15,000 barrels if you plan to export at least 75% of your beer. The cost to outfit a microbrewery with all the necessary commercial equipment is under $100,000. Compact devices require less storage space at home.

Real estate and tax savings will be substantial. You may count on a decrease in the price of your licence. Since you will be occupying a smaller space, you will have a lower long-term investment in things like plumbing, electrical, and flooring.

The day-to-day running of the business will be simple, and you may hire some help if you need it.

Beer Production Capacity

Commercial brewery equipment prices vary widely depending on several factors: brewery size. You'll need the more extensive brewing apparatus and brewhouse if your enterprise is on the grander scale.

The equipment of a brewhouse includes a lauter tun, boiling kettle, whirlpool, mash mixer, and hot liquor tank. The brewhouse's capacity is often expressed in barrels (bbl. ). Our company, like many others, can produce the brewhouse in a range of barrel sizes to suit the needs of our customers.

Brewhouse retail pricing varies by capacity as well. An inexpensive brewhouse can be purchased for under $50,000.

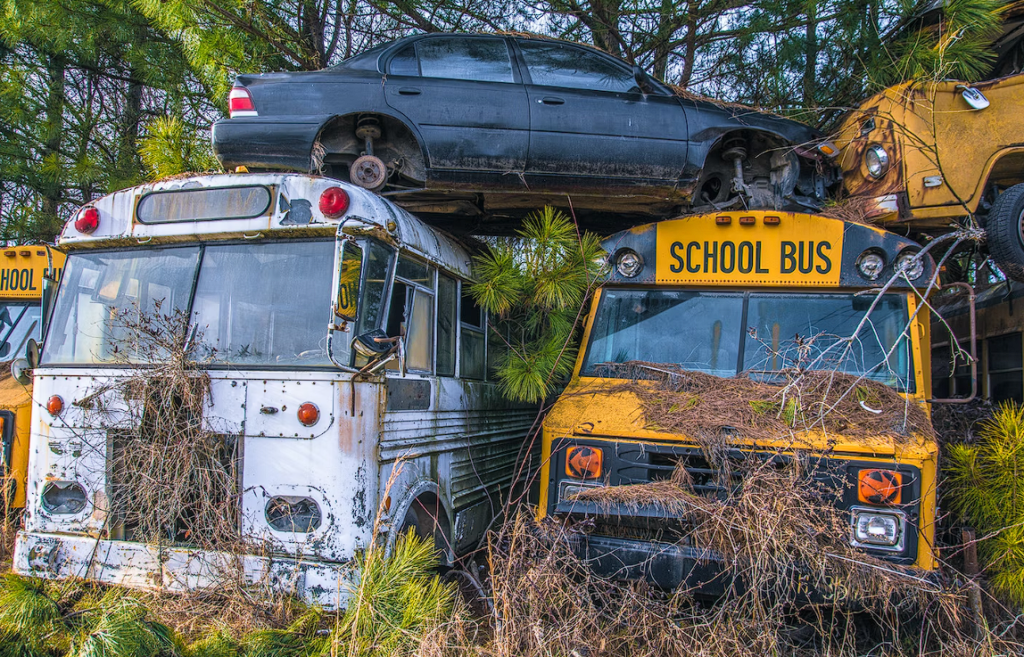

Brand New Or Used Brewery Machinery

The production costs will vary if you purchase new or secondhand equipment for your commercial brewery.

Old commercial brewing equipment from Craigslist may save you money if you verify its working condition before paying the seller. New equipment is more expensive, but it will help your brewing in any way.

Aside from the copper and stainless steel boilers and kettles, the following are other essential components of a commercial beer-making plant:

- The best fermenter to utilise is a jacketed one; a half-barrel non-jacketed one would set you back around $400, while a barrel fermenter of the same size will set you back over $3,200.

- The kegs are the standard container, and their $125 per unit price means you can save money by purchasing larger quantities. To clean them properly, you'll need to invest in a keg washer, which often costs less than $300.

Common Factors That Impact the Cost of Commercial Brewing

The cost of new technology often depends on three factors:

- What brand and model of brewing equipment do you use?

- What's your policy on taking either new or pre-owned brewing equipment?

- Approximately how big is your brewery?

Commercial Brewing Equipment

First, let's talk about the product side of breweries. In the same way, a kitchen might have glass, clay, stainless steel, or nonstick utensils, a brewery might use copper or stainless steel for its pots.

Brewery equipment can be expensive for a new business, depending on whether you buy new or used equipment. Of course, brand-new devices will be more costly than used ones, but this difference in cost should not affect your building.

If you purchase a used piece of industrial building equipment from a person on Craigslist, inspect it thoroughly before making any payment. In addition to the copper and stainless steel heating systems, boilers and pots, the following are other crucial components of commercial beer brewing equipment.

Beer Brewing Facility Size

The cost of industrial brewery equipment is primarily based on the brewery's size. You'll need the larger machinery and brewhouse to handle a more effective procedure. The least expensive brewhouse you may find could be around $50,000.

Business Development Start-up Costs

It can go between $100,000 to $1 million, but this depends on brewery size, certification, and investment in high-quality business-building tools. It'll be a business venture, and you can purchase all the commercial equipment you need to start a microbrewery for under a hundred grand. Smaller devices mean less clutter around the brewing house.

A Brewery startup is a high-investment endeavour that requires your complete focus and preparation for any challenges that may arise. If you work for a great company, your success is guaranteed.

A Brewery startup is challenging and expensive; you'll need dedication and a strategy to see you through. Those who work for a great organisation enjoy continuous success; thus, only the best is in your sights.

Minimum Essentials of Brewing

If you're here because you're thinking of starting a brewery, you might be wondering what essential tools you'll need to get started. As many others have learned before, brewing demands a sizable financial outlay.

This is a valid worry; numerous brewers have gotten their feet wet with minimal equipment, launched their products, found success in the marketplace, and expanded their operations by reinvesting their profits.

Grain Mill

Malt and other grains, such as wheat, are milled before being added to the mash. Having access to a mill of yours lets you regulate the fineness of the powder produced. Most breweries choose to install their own mill to maintain this level of control.

Depending on your location, you may or may not need a mill since some malt firms provide brewers with the option of purchasing pre-crushed malt and grains.

Hot Water And Hot Liquor Tank

You can't produce beer without water. Keeping the mash at a specific temperature requires paying close attention to the water temperature.

Beer that only meets quality standards will be produced if the temperature is just so. The hot liquor tank (or HLT) is a large stainless steel tank with its own heating system and is used by most breweries to store hot water for brewing and subsequent cleaning.

They're typically two times as big as the brewhouse. A brewery with a capacity of 500 litres would benefit from an HLT holding at least 1,000 litres.

Brewhouse

The wort is brewed in the brewhouse and transferred to the fermenters. A single vessel setup is possible. But this choice is very restrictive for brewers, so we will not suggest it.

With the mash contained in a "basket" and the strike water surrounding it, you mash in with only this one vessel. When the mash stand is finished, the basket can be hoisted above the kettle for the sparge and lautering processes.

It has the potential to produce high-quality beer, but it has severe limitations when brewing in larger quantities. Since it is necessary to complete one batch before beginning another. We've seen single-vessel breweries that can produce 500 litres at a time.

Heating Method

If your system capacity is less than one thousand litres and you're trying to save money, going the electric route is a good choice. It's less expensive than using direct fire or steam to heat a brewery, making it the most cost-effective option.

Being open for business might be more challenging if direct heat or steam is used due to constraints imposed by municipal legislation or the building code.

In most circumstances, the daily cost of electric operation is more than that of its gas counterpart. Also, more money may be needed to set up the brewhouse's electrical needs. More extensive than a thousand litres is possible with an electric brewhouse, but the cost of the necessary electricity rises rapidly as the capacity increases.

Thermal Fluid Heater

From the brew kettle, the wort is "flash cooled" in a heat exchanger before entering the fermenter vessel. Beer styles call for wort temperatures anywhere from 7°C to 35°C.

Heat exchangers typically have either one or two stages. The wort in a single-stage HXE is cooled with cold water from the cold liquor tank.

The HXE operates in two phases, the first using municipal water and the second using glycol. Glycol aids in reaching the desired temperature, but municipal/mains water handles the bulk of the cooling.

Brew Aerator

Typically, the wort is aerated after being cooled using HXE. Beneficial fermentations are the result of this aid for the yeast.

Typically, aeration occurs immediately following HXE. The wort aeration equipment is not prohibitively expensive and is well worth the additional outlay.

Tanks And Containers For Holding Liquids During The Fermentation Process

Once the yeast is introduced, Fermentation Vessels (FV) become magical places. Yeast converts the sugars in the wort into ethanol and the oxygen into carbon dioxide. To keep an FV at a constant temperature, it is typically "jacketed," meaning that a coil made of glycol is sandwiched between the FV's inner and outer layers.

It is essential to regulate FV's temperature; your beer will end up tasting sour. It's possible to have breweries with a variety of FV sizes. Typically, one, two, or three whole batches are made. A 500-litre brewhouse calls for FVs of 500, 1,000, and 1,500 litres.

Glycol

Breweries typically use glycol to cool wort and beer. In your brewery's heat exchanger and tank jackets, it will never come into contact with the beer. When it comes to chilling, a glycol system is in a league of its own, with its storage tank, pump, piping, and even chilling equipment.

Instrumentation Controls

Making beer requires at least a basic understanding of how the brewhouse and processes like fermentation work. The brewhouse and fermenting vessels/cellaring tanks in a brewery typically have their control.

To cut costs, it is possible to use a single control panel for multiple ships. The drawback is that your daily walking distance will increase. Brewery vessel temperature controls might be as basic as a panel with buttons, switches, and an LCD.

Pump For Transfer or CIP Equipment

Clean in situ pumps, which use internal spray balls, are a good option for cleaning tanks on the cheap. To clean a tank, you'll first need to fill it with water and chemicals, then use a CIP pump to transfer the mixture from the tank's base to a CIP arm equipped with a spray ball.

Cleaning Service For Kegs And Refrigerated Storage

Using a tank less than 35 per cent full at a brewery with a taproom on the premises is inefficient. In this step, the beer is transferred to kegs, and the tank is cleaned out for use with a different batch of beer. Most breweries will have a walk-in chiller for storing beer in kegs, as doing so will extend the beverage's shelf life. In addition to malt, yeast, and hops, breweries may often store other brewing ingredients in a walk-in.

Automation

Brewery automation makes brewing easier and helps maintain uniformity from batch to batch. Automation is pricey, but it's worth it to me to do things like step mash, where the mash is heated to a specific temperature and then turned off when it's done.

These are the bare minimum of gear required for industrial brewing. Good beer can be brewed with the tools mentioned above. You probably didn't enter this field expecting it to be simple, but you should be prepared to put in a lot of hard work.

Starting a brewery is costly and challenging; you will need dedication and a strategy to overcome obstacles. But excellent business always succeeds, so keep your fingers crossed.

Frequently Asked Questions

Though used in varying proportions depending on the style being made, ALL beer is made from grain, hops, yeast, and water.

Craft beer is typically made in small batches by independent breweries, using traditional ingredients and methods. Industrial commercial beer, on the other hand, is produced on a larger scale by major corporations and is often made with less expensive ingredients and more automation. Additionally, craft beers tend to have a more unique and diverse flavour profile, while industrial commercial beers tend to have a more consistent taste.

Craft beer is better than domestic beer because it is not mass produced, so more time is focused on taste and not watered down. Craft beer contains more alcohol, about 5-10 percent alcohol by volume vs 3.5 percent alcohol ABV offered by domestic beers. Craft beer offers more health benefits than your average red wine

Beer production involves malting, milling, mashing, extract separation, hop addition and boiling, removal of hops and precipitates, cooling and aeration, fermentation, separation of yeast from young beer, ageing, maturing, and packaging.

According to the Brewers Association, by 2020, craft breweries made up 24% of the retail beer sales. Current predictions suggest that this market will grow a further 13% by 2024, increasing by 47.79 billion in value. The numbers certainly suggest that now is a good time to learn how to invest in craft breweries.

Conclusion

Depending on the scale of your brewery, licencing requirements, and the cost of top-tier commercial brewing equipment, the price tag could easily top $1 million. If you're just starting out, a microbrewery is your best bet. Because you will be living in a smaller area, your long-term expenditures for items like plumbing, electricity, and flooring will be less. Investing in brewery equipment, whether new or used, can be costly for a startup. Using a jacketed fermenter is recommended, as a non-jacketed half-barrel fermenter would cost close to $400.

Below that price point, you can find a brewhouse that won't break the bank. Starting a brewery is difficult and expensive, so you need to be committed and have a plan to succeed. It can range between $100,000 to $1,000,000, depending on the brewery's size, level of accreditation, and commitment to high-quality business-building tools. These are the basic necessities for anyone thinking about opening a brewery. More than a thousand litres per batch can be made in an electric brewhouse, but the price per litre rises sharply as output volume grows.

All three sizes of FVs (500, 1,000, and 1,500 litres) are required for a brewhouse that holds 500 litres. With its own dedicated tank, pump, pipe, and sometimes even cooling apparatus, a glycol system stands apart from the others. A CIP pump is used to move the cleaning solution from the tank's base to the CIP arm's spray ball for effective cleaning. Automation in breweries facilitates brewing and ensures consistency from batch to batch. Beer stored in kegs in a walk-in cooler can be kept fresh for much longer, thus most brewers use one. You definitely didn't get into this area expecting it to be easy, but you still need to be ready to put in some serious hours.

Content Summary

- Grab your favourite brew and settle back; we're going to spend some serious time today learning about how beer is made in commercial settings.

- Throughout the world, you can find breweries of varying sizes and designs.

- Numerous people, likely in many roles, will be employed by a global brewery that is also vast and industrial.

- Each division of this brewery will be responsible for a distinct set of tasks, and its workers will see to it that these tasks are carried out solely in their area.

- Depending on the scale of your brewery, licensing requirements, and the cost of top-tier commercial brewing equipment, the price tag could easily top $1 million.

- Let me emphasise that this is just a ballpark figure.

- If you're just starting out, a microbrewery is your best bet.

- You'll have to squeeze in, but there's enough room to keep an eye on things.

- If you can sell at least 75% of your beer outside the country, you can get away with manufacturing fewer than 15,000 barrels.

- An entire microbrewery can be set up with commercial equipment for less than $100,000.

- Devices that are smaller in size take up less room in the home.

- There will be significant financial benefits in the areas of real estate and taxes.

- A drop in the cost of your licence is likely.

- Because you will be living in a smaller area, your long-term expenditures for items like plumbing, electricity, and flooring will be less.

- The number of barrels can be used to represent the brewhouse's potential output (bbl.).

- Like many others, our business is able to manufacture brewhouses in a variety of barrel capacities to meet the requirements of our consumers.

- The selling price of beer produced by a brewery varies according to its capacity.

- Below that price point, you can find a brewhouse that won't break the bank.

- Whether you buy new or used equipment for your commercial brewery, production prices will change.

- You might save money by purchasing used commercial brewing equipment from a seller on Craigslist, provided you first make sure the item is in good operating order.

- While investing in new equipment will increase your costs, it will improve your brewing in every manner.

- Other than the copper and stainless steel boilers and kettles, these are some of the most important parts of a commercial brewery:

- The ideal fermenter to use is a jacketed one, which can cost more than three times as much as a non-jacketed half-barrel fermenter (about $400) or a barrel fermenter (around $3,200).

- Kegs are the typical container, and at $125 each, buying in bulk is more cost-effective.

- A keg washer, which can be purchased for less than $300, is necessary for a thorough cleaning.

- There are typically three variables that affect the price of cutting-edge tech:

- Breweries employ pots made of copper or stainless steel, much as homes use glass, clay, stainless steel, and nonstick cookware.

- Investing in brewery equipment, whether new or used, can be costly for a startup.

- Though the price of new equipment will always exceed that of pre-owned equipment, this should not be a problem for your establishment.

- It can range between $100,000 to $1,000,000, depending on the brewery's size, level of accreditation, and commitment to high-quality business-building tools.

- All the commercial equipment you need to launch a microbrewery can be purchased for far under a hundred dollars, making this a viable business option.

- Having smaller electronics means less stuff to store at home.

- Starting a brewery is a high-risk venture that demands your undivided attention and thorough planning for every eventuality.

- Working at a top firm ensures your future prosperity.

- Starting a brewery is difficult and expensive, so you need to be committed and have a plan to succeed.

- Those lucky enough to work for an outstanding company have nothing but success in their goals.

- In case you've stumbled upon this page because you're considering opening a brewery, you may be asking what equipment is required.

- Brewing requires a large investment of capital, as many others have found out the hard way.

- This is a reasonable concern; many brewers have started small, introduced their products to the market, seen success, and grown their businesses by reinvesting their revenues.

- Before being added to the mash, malt and other grains such as wheat must be milled.

- You can control the consistency of the powder thanks to the mill at your disposal.

- In order to keep this level of control, most brewers opt to construct their own mill.

- Some malt companies provide brewers the option of purchasing pre-crushed malt and grains, thus having a mill isn't always necessary.

- Beer cannot be brewed without the use of water.

- It is crucial to monitor the water temperature in order to keep the mash at the correct temperature.

- To make beer of acceptable quality, the temperature must be just right.

- Most breweries employ a big stainless steel tank called a hot liquor tank (or HLT) equipped with its own heating system to store hot water used in the brewing process and subsequent cleaning.

- The mash is placed in a "basket," and the strike water is placed around it; thereafter, the entire "basket" is used for the mashing in process.

- When mashing is complete, the basket is lifted to the top of the kettle for the sparging and lautering operations.

- However, it has significant constraints when brewing in bigger volumes, despite having the ability to make high-quality beer.

- Since it's imperative to finish one batch before starting another.

- 500 litre batches can be made in single-vessel breweries.

- If you're looking to save money and your system's capacity is less than one thousand litres, adopting the electric route is a viable option.

- It's the most cost-effective alternative to using direct fire or steam to heat a brewery.

- If direct heat or steam is employed, complying with local legislation or the building code could make running a business more difficult.

- Daily electric costs are typically higher than gas costs in most cases.

- Electricity for the brewhouse may also require additional funding for installation.

- An electric brewhouse can have a capacity greater than one thousand litres, but the cost of the electricity required to do so grows dramatically.

- The brewing process begins with the wort being heated in the brew kettle and then transferred to a heat exchanger to be "flash cooled" before being poured into the fermenter.

- There is a wide range of wort temperatures required by different beer styles, from around 7 degrees Celsius to about 35 degrees Celsius.

- A heat exchanger may have a single stage or two stages.

- With a single-stage HXE, cold water is pumped from the cold liquor tank into the wort to chill it.

- The HXE has a dual-stage operation that begins with tap water and transitions to glycol.

- To achieve the required temperature, glycol is used in conjunction with municipal/mains water.

- After being cooled with HXE, the wort is usually aerated.

- This assistance for the yeast leads to more fruitful fermentations.

- Temperature control of FV is crucial to avoiding sour beer.

- A wide range of FV sizes can be found in breweries.

- One, sometimes two, and sometimes three complete batches are the norm.

- All three sizes of FVs (500, 1,000, and 1,500 litres) are required for a brewhouse that holds 500 litres.

- Glycol is commonly used in breweries for cooling wort and beer.

- The beer will never come into contact with it in your brewery's heat exchanger or tank jackets.

- A glycol system, which includes a storage tank, pump, piping, and cooling equipment, stands apart from the competition.

- A fundamental familiarity with the brewhouse and processes like fermentation is necessary for anyone interested in making beer.

- Breweries often have authority over their brewhouse and fermentation and storage tanks.

- One ship's control panel can be used by numerous vessels to save money.

- There is a downside in that you would have to walk further on a regular basis.

- Brewery temperature controls could consist of a flat panel with buttons, switches, and an LCD.

- Using internal spray balls, clean in situ pumps are a low-cost alternative for tank sanitation.

- Filling the tank with water and cleaning chemicals and then pumping the solution up the CIP arm and out the spray ball is the standard procedure for cleaning a tank.

- Tanks that aren't at least 35% full aren't being used to their maximum potential by breweries that feature on-site taprooms.

- The beer is racked into kegs and the tank is emptied before being reused for another brew.

- Beer stored in kegs in a walk-in cooler can be kept fresh for much longer, thus most brewers use one.

- Walk-ins are used to store a wide variety of brewing supplies, not just malt, yeast, and hops.

- Automation in breweries facilitates brewing and ensures consistency from batch to batch.

- Step mashing, in which the mash is heated to a precise temperature and then switched off when it is done, requires expensive automation, but it is well worth it to me.

- These items are the basic minimum for brewing operations at a commercial scale.

- The aforementioned equipment is all you need to create a tasty beer.

- You definitely didn't get into this area expecting it to be easy, but you still need to be ready to put in some serious hours.

- Brewery start-up is an expensive endeavour that requires commitment and forethought to succeed.

- Keep your fingers crossed, though, since good business always wins out in the end.